FRP Gratings

High Strength, Corrosion Resistant FRP Gratings for Industrial & Infrastructure Applications

In Enmetra Industries, we offer premium-quality FRP (fiberglass reinforced plastic) designed for industries that seek durability, corrosion resistance and mild structural support. Manufactured using advanced resin systems and constant fiberglass reinforcement, our FRP gratings are ideal choice for traditional steel and aluminum gratings especially in corrosive and high-moisture environment.

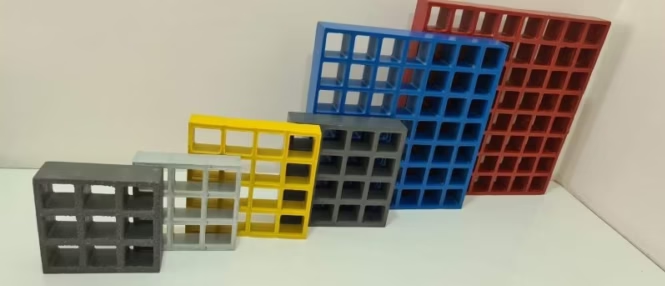

We supply both the standard and custom molded and pultruded available in different sizes, colors, resin and pultruded in the surface finish as per specific application needs.

Types of Gratings We offer

1. Molded FRP Gratings:

- Made by interweaving glass fiber strands in a mold and infusing with resin

- Provide excellent bi-directional strength and corrosion resistant

- Suitable for areas with frequent exposure to chemicals and moisture

2. Pultruded FRP Gratings:

- Manufacturing by continuous fiberglass roving through a resin bath and heated die

- Offers high unidirectional strength and stiffness

- Ideal for walkways, platforms and structure support applications

Standards & Technical Specifications

Our FRP Gratings comply with global quality and safety standards for industrial use.

Compliant With: ASTM E-84, ASTM D635, EN 13706, ISO 14122, ANSI A1264.1, OSHA 1910

Resin Systems: Isophthalic, Orthophthalic, Vinyl Ester, Phenolic

Mesh Sizes: Square/rectangular, 25 mm to 50 mm thickness

Finishes: Gritted top, concave, anti-slip coating

UV Stabilization & Fire Retardancy: Available on request

Load Ratings: Industrial duty, pedestrian and heavy-load classes

Gratings are available in square and rectangular mesh, with open area ranging from 30–70%, in thicknesses from 25 mm to 50 mm. Anti-slip surface coatings such as gritted top or concave finish are available for added safety.

Benefits of FRP Gratings

Corrosion Resistant: Ideal for chemical plants, marine, and wastewater sectors

Lightweight but Strong: 70% lighter than steel gratings with excellent load capacity

Low Maintenance: No rusting, no painting, long service life

Non-Conductive & Non-Sparking: Safe for electrical and flammable environments

Easy to Fabricate & Install: Can be cut, drilled, or assembled on-site without welding

Fire Retardant & UV Resistant: Optional enhancements available for harsh environments

Slip-Resistant Surface: Ensures worker safety in wet or oily areas

Applications

Our fiberglass gratings are widely used across sectors such as:

Chemical & Petrochemical Plants

Water & Wastewater Treatment Facilities

Offshore Platforms & Marine Docks

Power Plants & Substations

Food & Beverage Processing Units

Pulp & Paper Mills

Public Walkways, Trenches, and Drain Covers

Cooling Towers & Rooftop Platforms

Why Choose Enmetra

- Direct Exporter of FRP Products from India

ISO-Certified Manufacturing Partners

Custom Sizes, Resin Grades & Colors Available

Pre-dispatch Quality Inspection & MTC Reports

Global Logistics Support to Middle East, Africa, Southeast Asia & Latin America

Safe & Secure Export Packaging

Competitive Pricing with Timely Deliveries

One-stop Solution for Sourcing, QC & Shipping